SYNERGY WOOD® FAQS

T&G JOINT PATTERNS

T&G 101: WHAT IS V-JOINT, NICKEL JOINT AND SQUARE EDGE?

All Synergy Wood products are made with tongue and groove joints. Tongue and groove is the preferred method of fitting our wood boards together, edge to edge. Tongue and groove joints allow two wood planks to be joined strongly together to make a single flat surface and conceal the effect of wood shrinkage. "Tongue and groove" is often abbreviated as T&G.

All Synergy Wood products are made with tongue and groove joints. Tongue and groove is the preferred method of fitting our wood boards together, edge to edge. Tongue and groove joints allow two wood planks to be joined strongly together to make a single flat surface and conceal the effect of wood shrinkage. "Tongue and groove" is often abbreviated as T&G.

Each piece has a slot (the groove) cut all along one edge, and a thin, deep ridge (the tongue) on the opposite edge. The tongue projects a little less than the depth of the groove. Two or more pieces fit together closely.

Our wood boards are also end-matched. This method eliminates the need for additional joints, face nailing or the use of joints on framing.

V-JOINT:

The term "V-Joint" comes from the "V" created when two of our T&G boards come together. They form a V between the two boards. The T&G V-Joint pattern is used in our very popular Synergy Collection. The V-Joint pattern is often used in our wood ceiling applications.

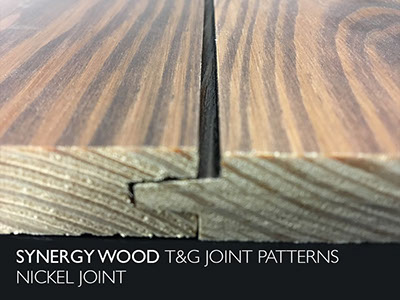

NICKEL JOINT "SHIPLAP" LOOK

The term "Nickel Joint" or Nickel Gap" comes from the old craftsmen using actual nickels to space the wood - the width of a nickel. Our T&G profile has a square edge profile with a 1/8″ gap between the boards to ensure a seamless nickel gap. Nickel gap also gives the appearance of Shiplap but with a much stronger joint, ability to blind nail (hide the nails behind joint) and still have end-matching. Nickel joint is a clean look that is often used on wood walls and in replace of a shiplap look.

V-JOINT

NICKEL JOINT

WHAT IS END-MATCHING? WHY IS IT BENEFICIAL?

End matching is the process of double end-trimming each plank using boards milled with a tongue and groove on the plank ends. This provides a male and female end, allowing the boards to be interlocked during installation and creating a mechanical bond. When boards are interlocked through end-matching, cupping potential is eliminated and wood expansion and contraction are tolerated.

WHAT GRADE WOOD IS USED IN SYNERGY WOOD? WHAT DOES IT MEAN?

We use #2 and C Southern Pine and SB Red Grandis

Red Grandis SB allows for some limited knots and small color variation

#2 Southern Pine allows for large knots and some color variation

C Southern Pine is mostly clear, occasional tight knot

Click on our Synergy Grading Guide to learn more about the grades of our wood.

SYNERGY WOOD®

SYNERGY WOOD®

Our showroom is open to visitors Monday through Friday from 8am - 4pm. Can't make it to our showroom? Order wood wall board samples today.

3031 S Mellonville Ave 866.791.6714

Sanford, Florida 32773 info@synergywood.com

© 2023 Synergy Wood®. All Rights Reserved. Synergy Wood®, E-Peck® and the "S" logo mark are all registered trade marks of Synergy Wood Products, Inc.